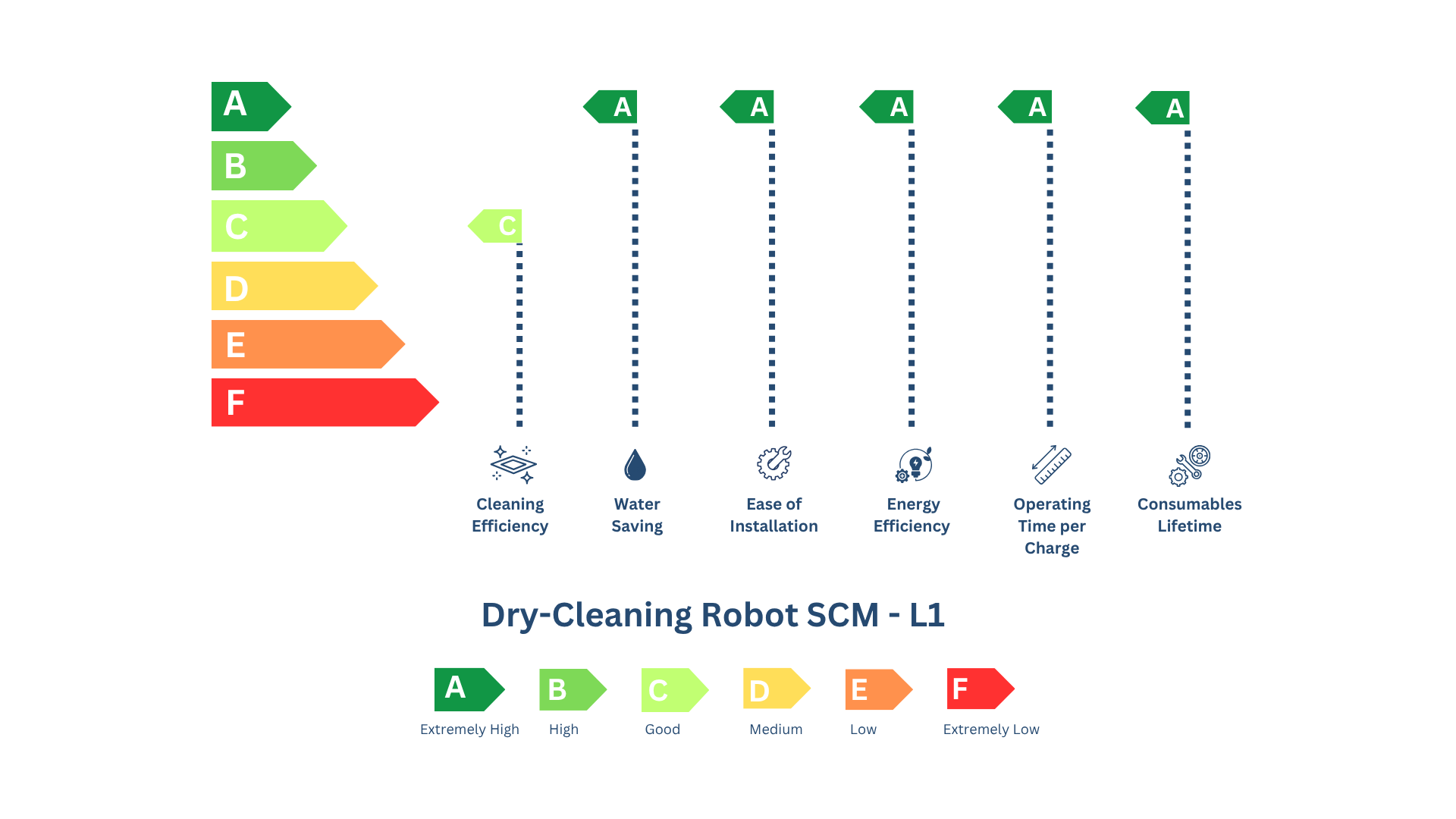

The Dry-Cleaning Robot SCM - L1

The SCM-L1 Dry Cleaning Robot is a waterless cleaning robot that uses carefully designed and manufactured rotating brushes, made from specially selected materials, to gently and effectively remove dust and dirt from solar panels. This model achieves 100% water savings, offers exceptional energy efficiency, features a quick and hassle-free installation, and is capable of cleaning a large number of panels on a single charge.

Monitored & Controlled via DarbSense IoT Platform

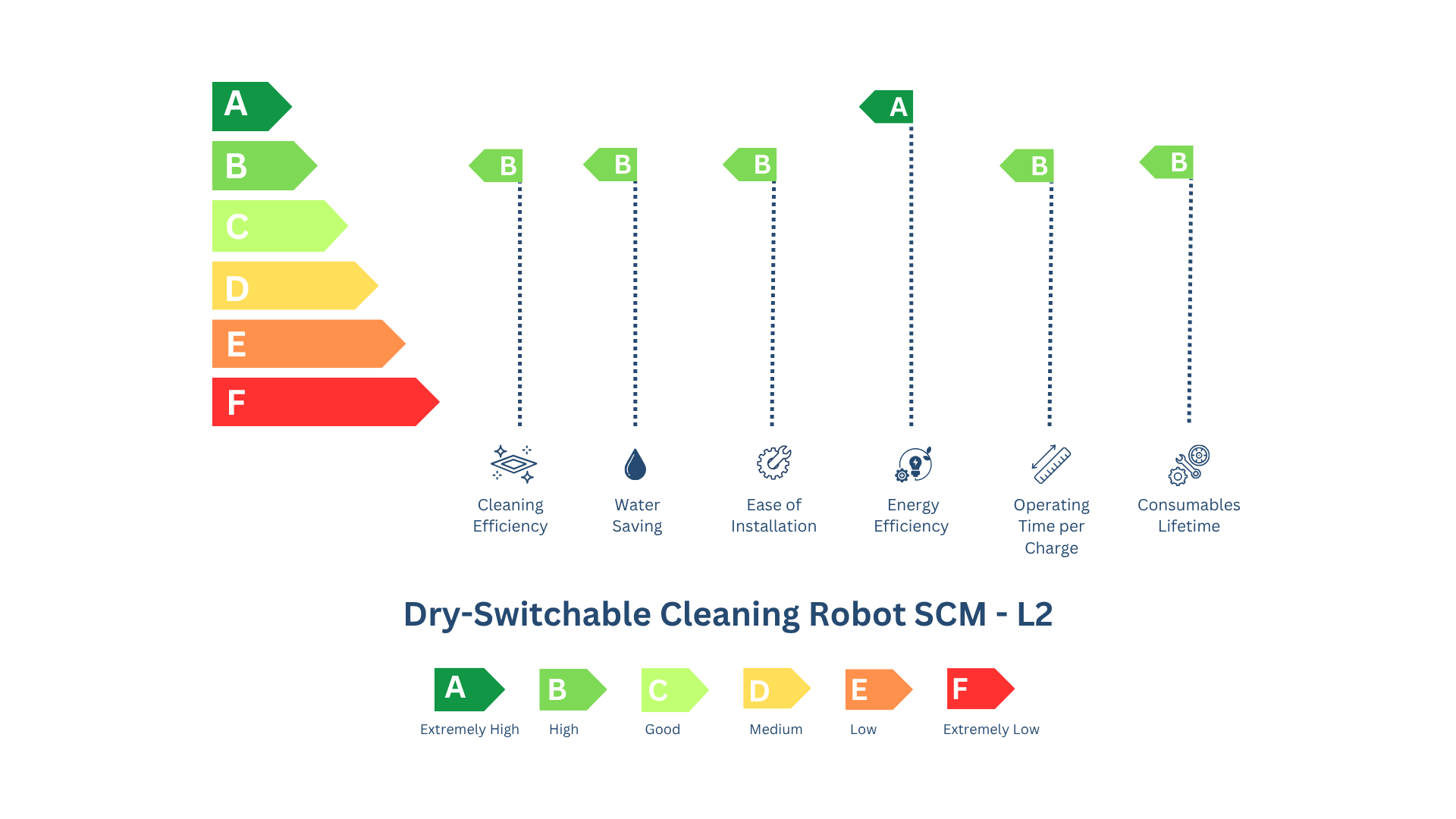

The Dry-Switchable Cleaning Robot SCM - L2

The SCM-L2 Dry Switchable Robot is designed with advanced cleaning technology that allows users to switch between dry and wet cleaning modes. This flexibility ensures optimal cleaning based on the specific needs of a solar plant. If your maintenance schedule requires both dry and wet cleaning cycles, the SCM-L2 can accommodate them without the need for additional materials lor extra costs, making it a cost-effective and efficient solution for solar panel maintenance.

Monitored & Controlled via DarbSense IoT Platform

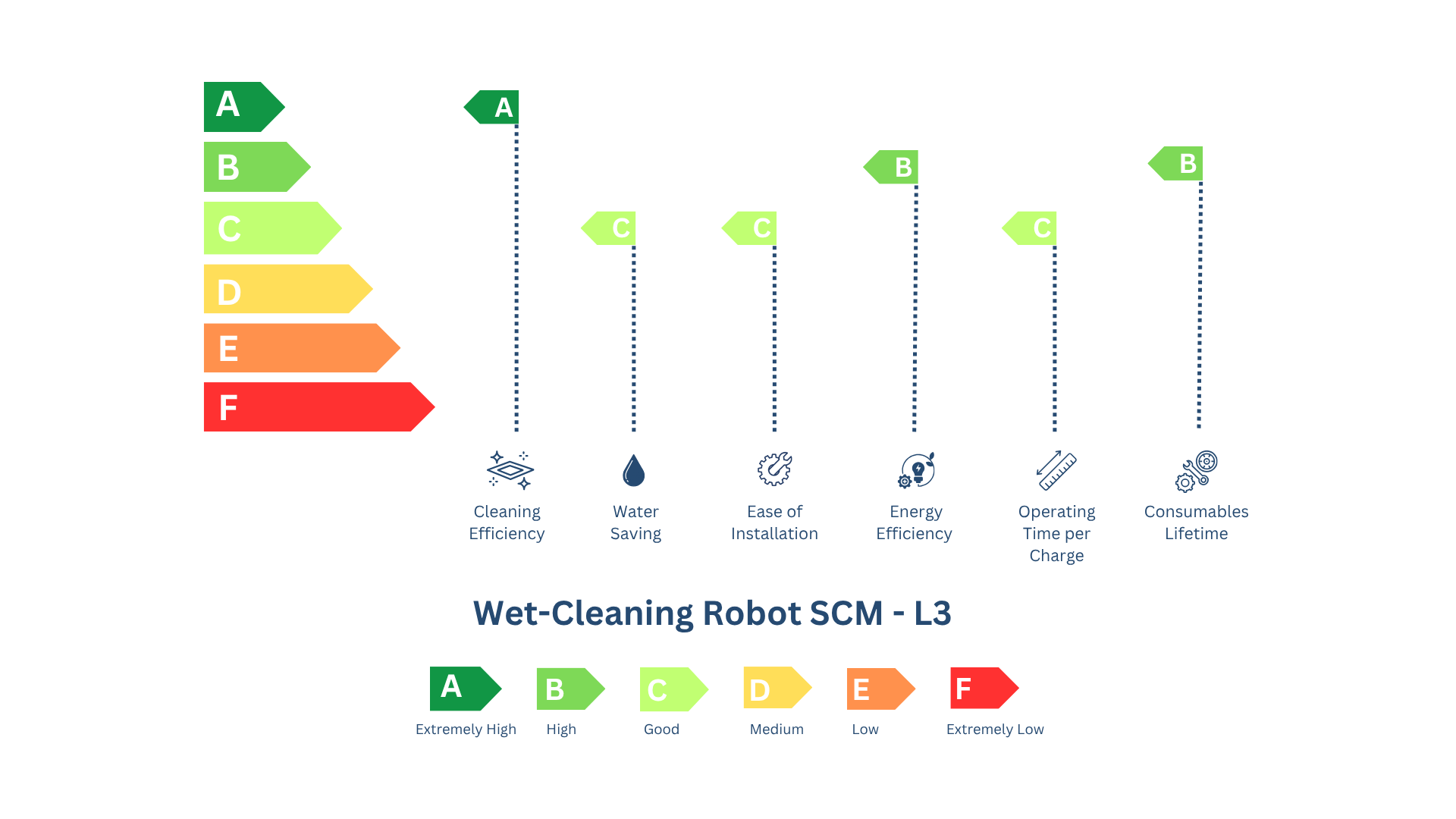

The Wet-Cleaning Robot SCM - L3

The state-of-art SCM-L3 Wet Cleaning Robot uses a the unique three-stage process, water spraying, brushing, and wiping, guarantees 99% dust removal of the tough, sticky dirt, and debris, and birds drops, ensuring maximum solar panel efficiency and leaves you solar panels crystal clear.

Monitored & Controlled via DarbSense IoT Platform

Dust-eye

The Dust-eye is a soiling monitoring system that provides continuous, real-time data tracking of soiling levels, and enables data-driven panels cleaning cycle trigger. It seamlessly integrates with your robotic cleaning system and DarbSense IoT platform.

Monitored & Controlled via DarbSense IoT Platform